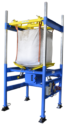

Bulk Bag Unloaders

BPS offers bulk bag unloaders, also known has unloaders, built to suite your operation’s needs. Multiple configurations are available, starting with our primary equipment models; the MTD, with air cylinder agitation, and BBD, equipped with vibratory motor agitation. Your bulk bag unloaders is fabricated for your specific service, including frame design and sizes, standard and heavy duty and loading/unloading method. Browse through our Bulk Bag unloaders models by clicking a name on the list below. For more detailed information please contact us.

Each bulk bag unloader is outfitted with standard features and can be customized with optional functionality:

- Every unloader is equipped with BPS’s Bag Transport Frame – which is designed for both fork truck and crane or hoist pick-up. The innovative tee handles with spring return, keeps bag loops in a safe, yet easily removable position.

- Our Self-Contained Chain Type Hoists are 2-ton capacity and are supplied with a pendant operator control and a manual trolley. Lift speed is 16 FPM, as standard. A powered trolley is optional. Trolley speed is 60 FPM as standard. Basic lift/travel is 10 ft. Air hoists for hazardous areas are available in a spark-proof design. Unloaders can be supplied for use with a customer crane, or in a crane bay for multiple unit unloading.

- All BPS unloaders include a bag untie hopper, with hinged access door, this enables the operator to untie the bag discharge spout, with the total weight of the bag safely supported. A dust-control port ensures airborne dust isn’t an issue during untying. A sanitary food produce design is also available with a special spout clamping feature for internal bag liners.

- All standard bulk bag unloaders incorporate a neoprene facial seal with 17” diameter discharge outlet for a dust-tight operation. White neoprene is available for FDA-approved requirements.

- Our Pincher Option consists of two UHMW elliptical pincher bars powered by individual air cylinders, to close off the bag spout for removal of partially unloaded bags. The access door is provided with safety interlock to prevent cylinder closing with the door in the open position.

- An optional liner tensioner mechanism can be mounted on top of the bag transporter frame to prevent the plastic liner in bulk bags from extruding downward into ancillary feeding equipment during the unloading process. It is a spring-loaded, hand-crank device with bag attachment clip.

- The Bag Extension Feature is a design where the upper-most bag transporter support frame of the discharger is mounted on four permanently gas-filled cylinders. As load in the bulk bag is diminished, the frame raises the bag, elongating the bag nose, for more effective unloading.