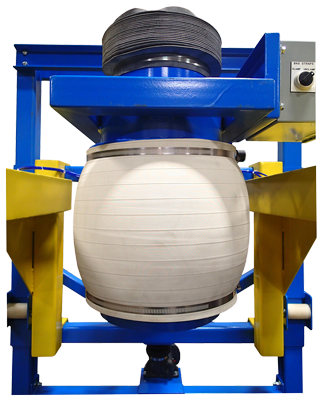

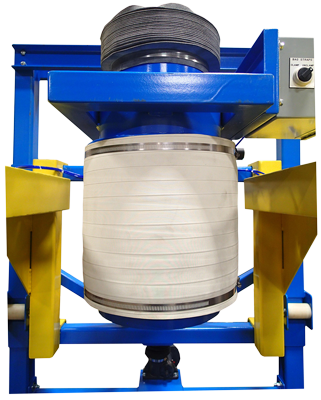

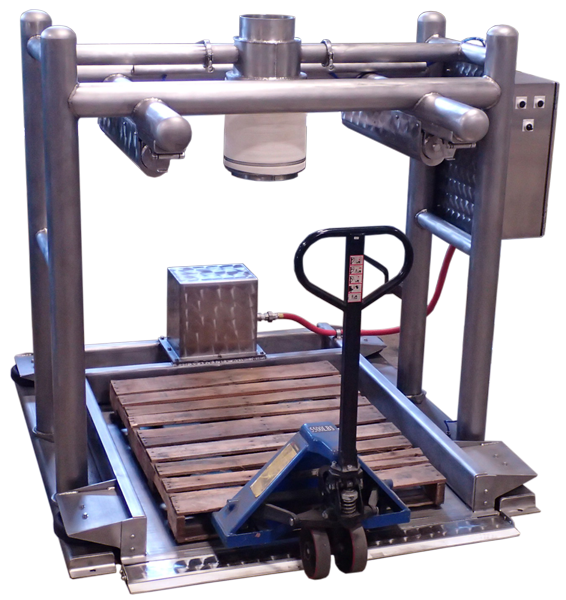

Bulk Bag Fillers

Our Model BBF (Bulk Bag Filler) is designed to fill any size bulk bag with high accuracy. With a proven low maintenance design, our bulk bag fillers offer years of trouble-free maintenance.

In addition to our standard components, BPS also offers custom equipment to suit all your filling needs. Get tips on how to select the right Bulk Bag Filler.

See the optional features tab, below, for more information. For any additional options or custom fabrication, please contact us.

- Inflatable fill head that offers a dust free seal when loading.

- Operator slides the spout of the bulk bag over the fill head and turns the selector switch to “Inflate”. The fill head inflates providing a dust free seal for filling. Once the bag is full the operator then turns the selector switch to “Deflate” and removes the bag.

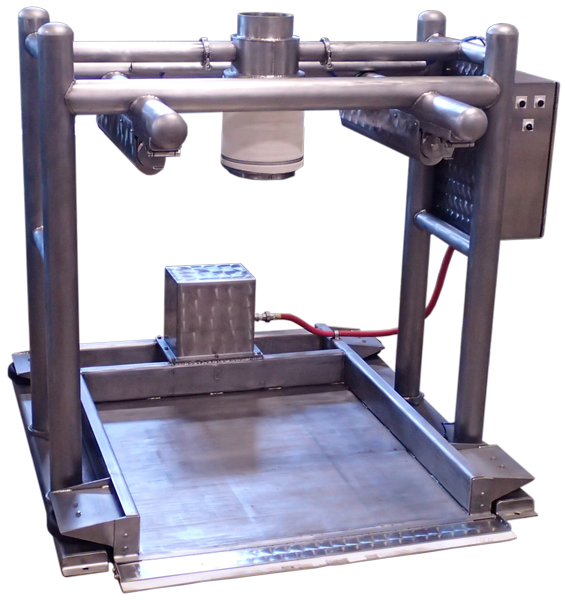

- Dust port with dust cartridge

- Retractable pneumatic bag strap support pins

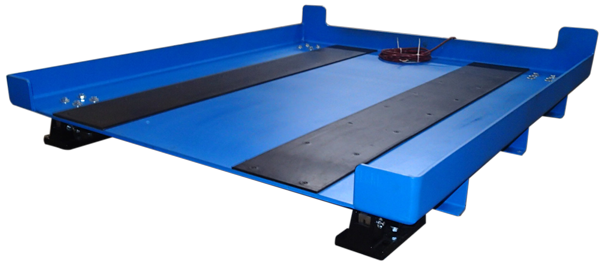

- Bag loading surface with pallet retaining flange on three sides

- Manually adjustable bag supports for varying bag heights 42”-60” high bags standard. (Consult factory for additional bag heights)

- No electricity is required for our standard bag fillers

- Great for low ceiling heights

- Vibratory Deck

- Flat Deck (Air/Electric)

- Grid Deck (Air/Electric) (for use with roller conveyor)

- Roller Conveyor (Gravity/Electric)

- Screw Jack (to allow for different bag heights)

- Air Cylinder, Electric or Manual

- Metering Device for loading

- Slide gate, rotary valve, screw feeder or vibratory feeder

- Bag Support Arm Extensions

- Bag support arm extend out to allow for easier access to the back bag loop supports (Manual/Air)

- Bag Inflation prior to filling

- Drum Adapter

- Attaches to fill head and allows for single drum loading

- Load Cells for accurate weighing

- System Controls

- Manual or Automated control system

- Material of Construction

- Mild Steel, 304 Stainless Steel or 316 Stainless Steel